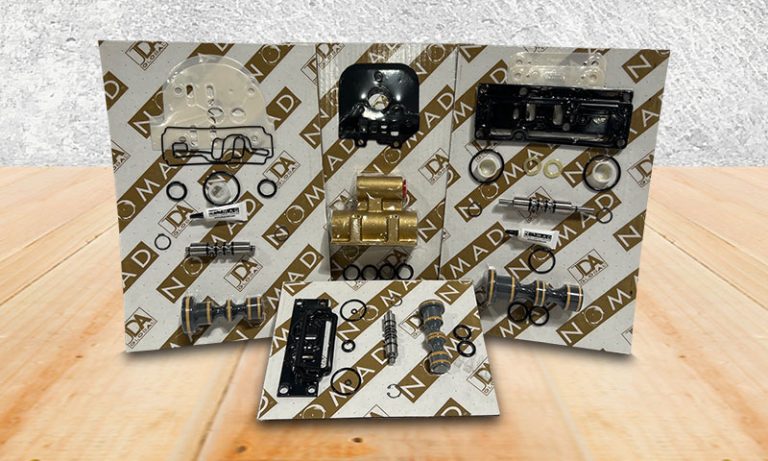

Diaphragms stand as the pulsating heart within the intricate machinery of a pump. Similar to the dynamic movement of contact lenses, these essential membranes transition from concave to convex, embodying a separation membrane that delineates the “dry” and “wetted” sides of the pump. The mechanical life of diaphragms is contingent on factors such as air volume, pressure, and the nature of the transferred chemical. Given the perpetual movement and flex, diaphragms emerge as key wear parts, necessitating regular evaluation. Much like ball valves, diaphragms are available in an array of materials, allowing for precise selection to match application specifications, from extreme temperature variations to highly abrasive or chemically aggressive substances. Refer to the “ball valve” section for a comprehensive list of available diaphragm materials.

What is a Diaphragm?

A diaphragm, within the context of pumping mechanisms, refers to a flexible membrane that undergoes rhythmic movements, transitioning from a concave to convex shape. This crucial component serves as a separation barrier between the air and liquid sides of the pump, ensuring precision and control in fluid transfer.

How Do Diaphragms Work?

The operation of diaphragms mirrors the natural movement of contact lenses, flexing and adapting to the demands of the pumping cycle. As the diaphragm transitions between concave and convex shapes, it creates alternating suction and discharge phases, facilitating the rhythmic transfer of fluids. This constant movement, while integral to the pumping process, designates diaphragms as key wear parts. Regular evaluation is essential to ensure optimal performance and longevity.

Applications of Diaphragm Pumps with Diaphragms

- Chemical Processing: Diaphragm pumps featuring resilient diaphragms find crucial applications in chemical processing, where precise and reliable fluid transfer is paramount. The ability to withstand chemically aggressive materials makes diaphragm pumps a preferred choice in such environments.

- Medical Devices: In medical devices, diaphragm pumps play a vital role in ensuring the precise handling of fluids. The controlled movement of diaphragms contributes to the reliability required for various medical applications, such as drug delivery systems.

- Industrial Processes: Diaphragm pumps with versatile diaphragms prove invaluable in industrial processes requiring pulsation-free pumping. The adaptability of diaphragms to handle diverse materials and conditions makes them a reliable choice for consistent results in industrial settings.

In conclusion, diaphragms serve as the dynamic core of pump systems, embodying versatility and reliability in fluid transfer across a spectrum of applications. Their unique design and adaptability make them indispensable for achieving precision, control, and longevity in pumping operations.